Continuity in Manufacturing

In addition to prototypes and small series, we have also intensified our production of series parts in recent years.

We typically produce between 50,000 to 200,000 units of a part per year and mainly deliver to the automotive and medical devices industries.

In many of our projects we deal with multi-component or 2C parts, hard-soft combinations or overmolded metal or plastic parts and fabrics.

We implement our customers’ requirements precisely in our production and provide open and transparent processes, efficient project management and continuous quality assurance – all on the basis of our comprehensive experience over many areas of manufacturing engineering. Aligned with our customers’ global procurement processes, we have finely tuned our offering to respond to their cost consciousness while, at the same time, meeting the highest demands regarding quality.

By keeping design, development and tooling resources available in house and by using service resources from around the world we are in a position to organize series manufacturing on an extremely competitive basis with exceptional quality and delivery performance. We respond quickly and intelligently to challenges of every kind and continuously improve our own processes.

EXPERTISE AND RELIABILITY

Benefit from our experience.

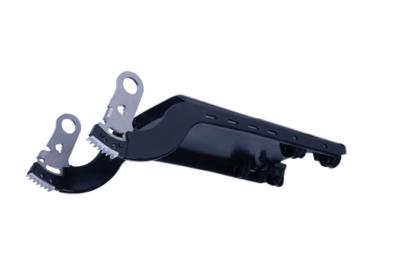

Component for center armrest

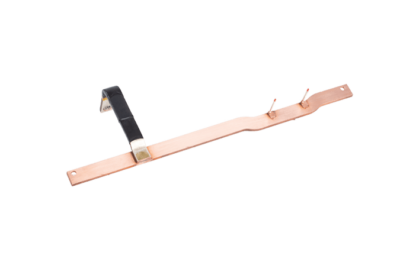

Busbar

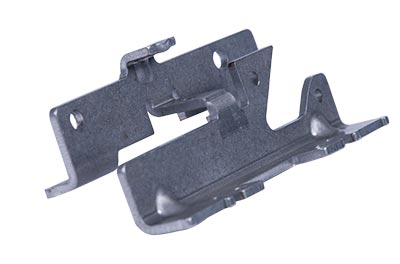

Flap

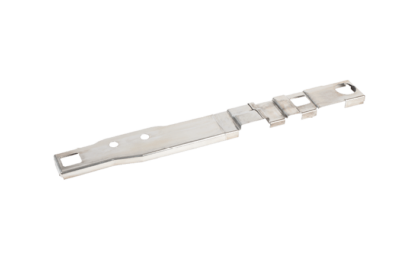

Guiding Rail

Guide

Fixation

Battery cell holder

Overmolded PCB

Charging plug

Overmolded stamped bent part

Assembly overmolded

Roof front assembly

Round bar with springs, overmolded

Overmolded stamped bent part

Roof slider

Cable with pin and lug

Deep-drawn part, shielding

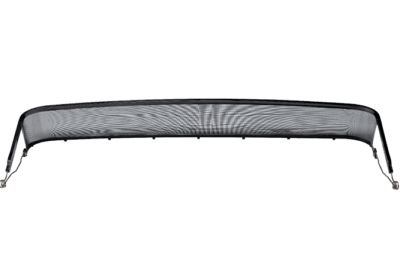

Wind deflector, overmolded fabric

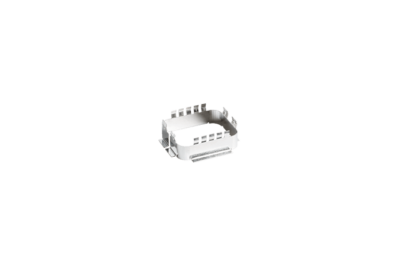

Shielding of plug

Bent spring, overmolded

Shielding of flexible busbars

Medical device

Cap, medical technology